Capabilities

Design & Engineering

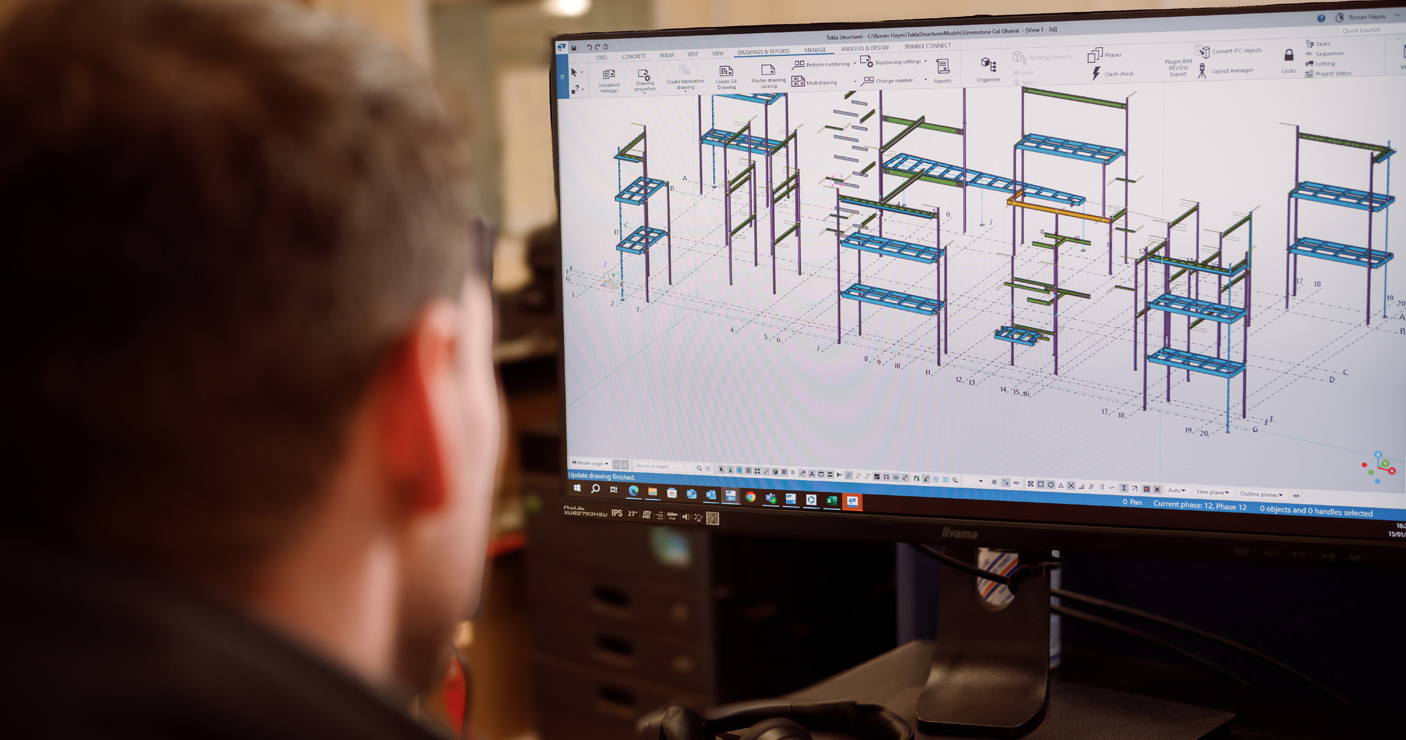

- Highly-experienced specialist detailing team, tailored specifically for integration with offsite Modular construction.

- Versatile 3D modelling using Autodesk REVIT & TEKLA Structures software, producing precise and high-quality fabrication drawings.

- Intelligent 3D model collaboration with customers through BIM technology including M&E contractors.

- Technical support provided from the early design phase through to project completion in line with customer requirements.

- Trimble X7 3D Laser Scanner & Point Cloud Technology.

Capabilities

Manufacture & Steel Fabrication

We take an engineering approach to every job, instituting systems and using the latest technology that ensures quality and cost efficiency.

- Certified factory production control (EN1090-1) & welding procedures (EN1090-2) Execution Class 3

- StruMIS Production Management to maximise productivity

- Experienced fabrication workforce, fully trained to meet refined tolerances.

- Automated FICEP Endeavour CNC saw & drilling line.

- Automated 4 Turbine Pre-fabrication Gietart Shot-blaster to Swedish standard SA2.5

- Plate processing comprising of FPB1800 Peddinghus and Morgan Rushworth ACP Plasma Profiling System

- Paddinghaus Anglemaster AFPS643 Angle processing

- Morgan Rushworth 4100/240 CNC Pressbrake

- Fully heated painting facility

- Intumescent fire protection FIRETEX 6002

- Hot Dip Galvanising to BS EN ISO 1461

- Large on-site storage capacity

Delivery & Construction

We boast a highly trained construction workforce. Working closely with the project management team, they are leaders in steel erection and always utilise the latest equipment on site.

The nature of our work puts a great emphasis on the quality of the people employed, their training, and the provision of modern equipment.

Our health and safety team monitors all sites on a regular basis to make sure these essential standards are maintained

Quality & Safety

- High quality standards achieved through innovative quality engineering.

- ODS strongly believe in the ‘Zero Error’ production concept.

- CE Marked to BS EN 1090 standards EXC 3.

- ISO 9001 – Certified Management System.

- SCCS Certified.

- Fully qualified CSWIP 3.0 plus visual welding inspector.

- Full traceability, quality & technical documentation provided on completion.

- ISO 45001

Have a Project Planned?

Enquire now